PRODUCTS

- Products

- Turbine Valve Actuator Tester (TVAT)

-

Necessity of Performance Prediction Diagnostic Tester(TVAT) before malfunctioning

-

Performance Prediction Diagnostic Tester (TVAT) for Turbine Valve ActuatorsActuator diagnostic 3D ImageContamination of hydraulic oil due to internal damage of actuatorNecessity of Performance Prediction Diagnostic Tester(TVAT) before malfunctioningDifferences from existing similar product technologiesPerformance Prediction Diagnostic Test-1Diagnosis of soundness by special diagnosis block modulePrediction Diagnosis Algorithm ConfigurationExpected EffectReal time failure prediction monitoring system(Option)

- Turbine Valve Actuator Tester (TVAT)

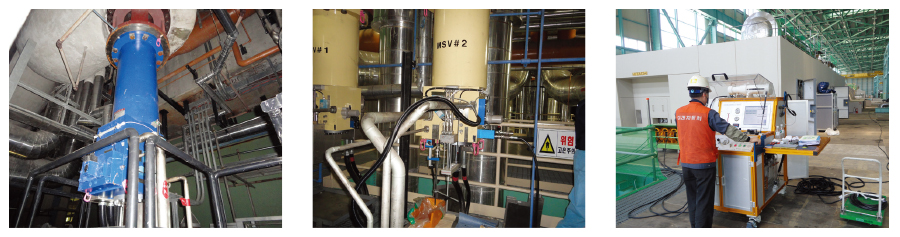

- Performance Prediction Diagnostic Tester (TVAT) for Turbine Valve Actuators

- Actuator diagnostic 3D Image

- Contamination of hydraulic oil due to internal damage of actuator

- Necessity of Performance Prediction Diagnostic Tester(TVAT) before malfunctioning

- Differences from existing similar product technologies

- Performance Prediction Diagnostic Test-1

- Diagnosis of soundness by special diagnosis block module

- Prediction Diagnosis Algorithm Configuration

- Expected Effect

- Real time failure prediction monitoring system(Option)

- Hydraulic System

- Vacuum System

- General Industrial Equipment

Necessity of Performance Prediction Diagnostic Tester(TVAT)

before malfunctioning

- Turbine Valve Hydraulic Actuators are core devices of nuclear power plants and thermal power plants. Although high durability and reliability are required, the present inspection method can only carry out limited maintenance to specific hydraulic actuators such as troublesome actuators due to the characteristics of power plant. It can only be diagnosed with disassembly of actuators from the system.

- It is a portable on-site performance prediction diagnostic tester that doesnŌĆÖt have to go through the inconvenience of disassembly of the hydraulic actuator. It saves huge maintenance cost and allows the full inspection within a fixed maintenance period.

- Actual preventive maintenance is possible through preliminary full inspection and performance evaluation with TVAT.

- Ensures reliability of power generation maintenance through power plant self-certification test before installing system.